From Steam to Smart: Why Industry 5.0 Is the Next Great Leap in Business Transformation

Industrial revolutions have always reshaped the industrial ecosystem and global economy, creating winners and losers among companies and nations. Today, we stand on the threshold of Industry 5.0, a new era where humans and machines do not just coexist but collaborate to deliver personalization, resilience, and sustainability at scale.

Unlike the hype cycles around emerging technologies, this shift is not optional. Companies that understand its drivers, quantify its impact, and execute strategically will unlock significant competitive advantage. Those that ignore it risk being disrupted faster than they expect.

This blog explores how we got here, what is driving this wave, and what leaders can do to navigate it successfully.

A Look Back: Four Industrial Revolutions

Each industrial revolution was a step-change, not an incremental advance, fundamentally altering how value was created, how companies competed, and how people worked.

- Industry 1.0 – Mechanization (late 1700s): Steam power enabled mechanized production, with textile mills producing 10x the output of artisanal workshops. The steam engine also gave rise to railroads, mining, and steel, transforming trade and logistics.

- Industry 2.0 – Electrification & Mass Production (late 1800s): Electricity and assembly lines drove efficiency at scale. Ford cut Model T production time from 12 hours to 90 minutes, while interchangeable parts revolutionized aerospace and defense. Productivity gains were measured in orders of magnitude, fueling mass consumer markets.

- Industry 3.0 – Digitization (mid-20th century): Computing, electronics, and robotics enabled automation and precision. PLCs and industrial robots cut manufacturing errors by up to 80%, while just-in-time systems and lean production allowed companies like Toyota to eliminate waste and improve responsiveness.

- Industry 4.0 – Connected Intelligence (early 2000s): IoT, cloud computing, and AI connected cyber and physical systems. Machines communicated in real time, enabling predictive maintenance that cut downtime by up to 50%. McKinsey found that digital supply chains reduced lead times by 20–30% and improved inventory turns by 25%. Data itself became a strategic asset.

The Current Transition: Industry 5.0

Every revolution has redefined value creation. The same is happening now, with one crucial distinction: Industry 5.0 puts humans back at the center, collaborating with intelligent systems rather than being displaced by them.

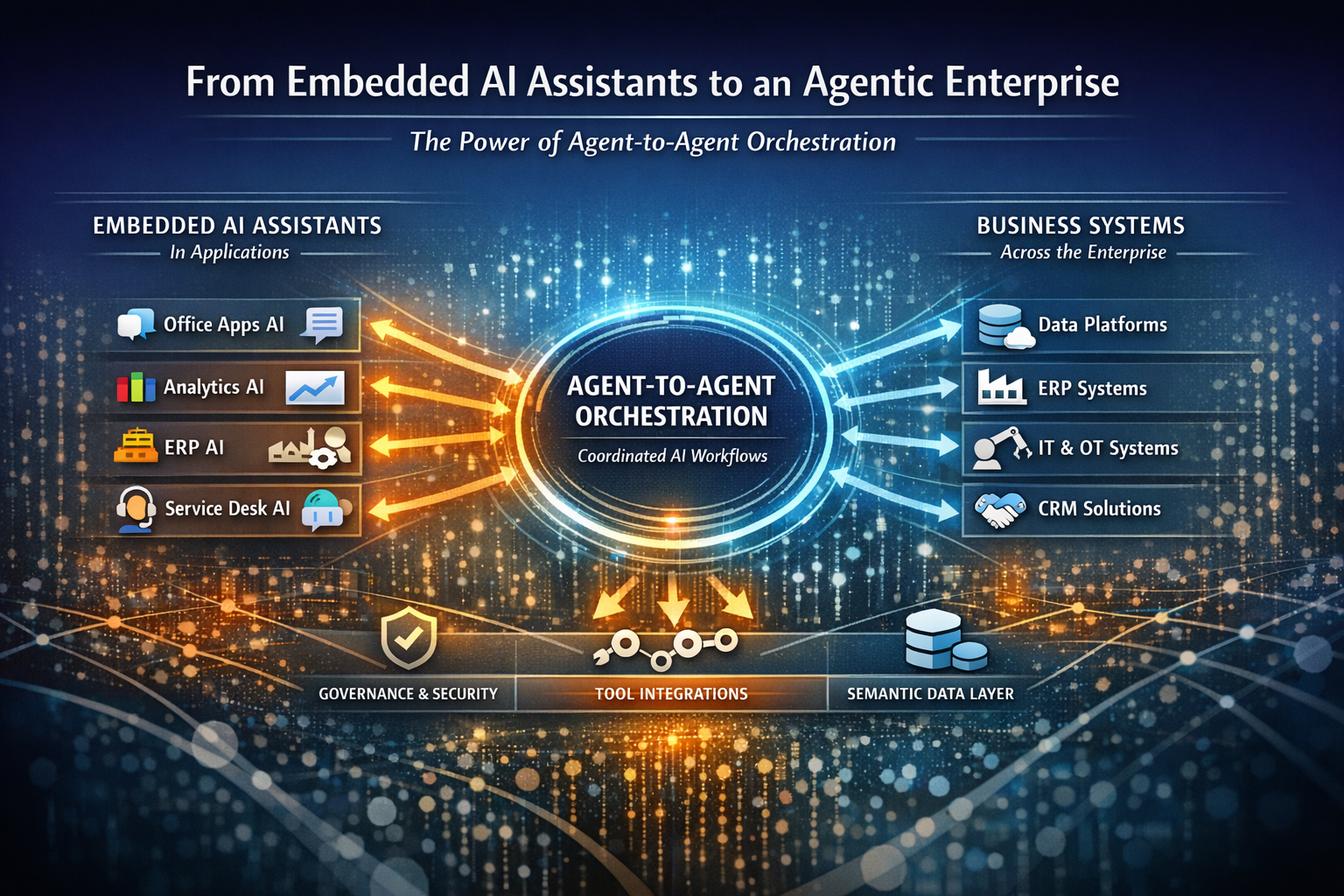

Where Industry 4.0 prioritized automation and efficiency, Industry 5.0 emphasizes augmentation and collaboration. Machines provide scale, precision, and speed; humans contribute creativity, judgment, and empathy. Together, they unlock new forms of value.

Industry 5.0 is built on four measurable pillars:

- Human–AI Collaboration: AI accelerates decision support, but accountability and context remain with people. Pharma companies use GenAI to identify molecules, while scientists guide validation. Human-in-the-loop AI can deliver 20–40% faster decision cycles (BCG).

- Sustainability by Design: ESG imperatives are embedded into operations. Unilever’s digital twin program cut supply-chain carbon emissions by 30%, and McKinsey estimates sustainability-linked efficiencies can improve margins by 5–10%.

- Personalization at Scale: Advanced customization now drives revenue growth without cost penalties. Deloitte reports firms with personalization strategies achieve 2–3x higher revenue growth, while BMW’s customer-configured factories deliver high-margin vehicles efficiently.

- Responsible Innovation: Ethics and governance are differentiators. PwC found 85% of executives believe responsible AI directly impacts trust and adoption. Industry 5.0 turns compliance into competitive advantage.

Industry 5.0 is not just the next stage of industrial evolution, rather, it is a rebalancing of the relationship between people and technology, building enterprises that are more human, sustainable, and resilient.

What’s Driving This Wave?

Every industrial revolution has been powered by a convergence of forces - technological breakthroughs amplified by economic, social, and cultural shifts. Industry 5.0 is no different. What distinguishes this wave is not just the speed of innovation but the alignment of market, workforce, and investment forces pushing in the same direction.

- AI & GenAI breakthroughs: McKinsey projects GenAI could add $2.6–4.4 trillion annually to global GDP, accelerating R&D, reducing downtime, and enabling contextual intelligence.

- Sustainability and ESG pressures: With $2.5 trillion in ESG-focused assets under management (BlackRock), investors are rewarding companies that align with climate and social imperatives.

- Supply chain volatility: After COVID-19 and geopolitical disruptions, 93% of supply chain leaders (Gartner) prioritize resilience. Digital twins and predictive analytics are now strategic necessities.

- Workforce expectations: Gen Z and Millennials want purposeful work. 65% are more willing to adopt AI if it enhances creativity, making augmentation more attractive than automation.

- Capital flows into digital transformation: IDC forecasts $3.4 trillion in annual global spend by 2026, led by manufacturing and financial services. Investors are validating the Industry 5.0 trajectory.

Together, these forces are not just creating momentum - they are making Industry 5.0 inevitable.

Real-World Momentum: Companies & Trends

Industry 5.0 is no longer a distant vision. It is already shaping the strategies of leading firms across sectors. From automotive to consumer goods to biotech, companies are proving that human–machine collaboration creates measurable business value.

- Tesla: Robotics deliver precision while humans ensure craftsmanship, driving ~30% gross margins before recent price adjustments.

- BMW: Smart factories integrate AI with human oversight, enabling mass customization without added lead time.

- Siemens & Schneider Electric: Building industrial metaverses with human-in-the-loop controls, reducing product development cycles by 20%+.

- Unilever: Uses digital twins to reduce emissions by 30% across global supply chains.

- Pharma/biotech: AI accelerates molecule discovery, while scientists validate, demonstrating human-AI symbiosis.

Capital markets are taking notice: industrial AI startups attracted $6.3B in 2024 (PitchBook), signaling strong investor confidence.

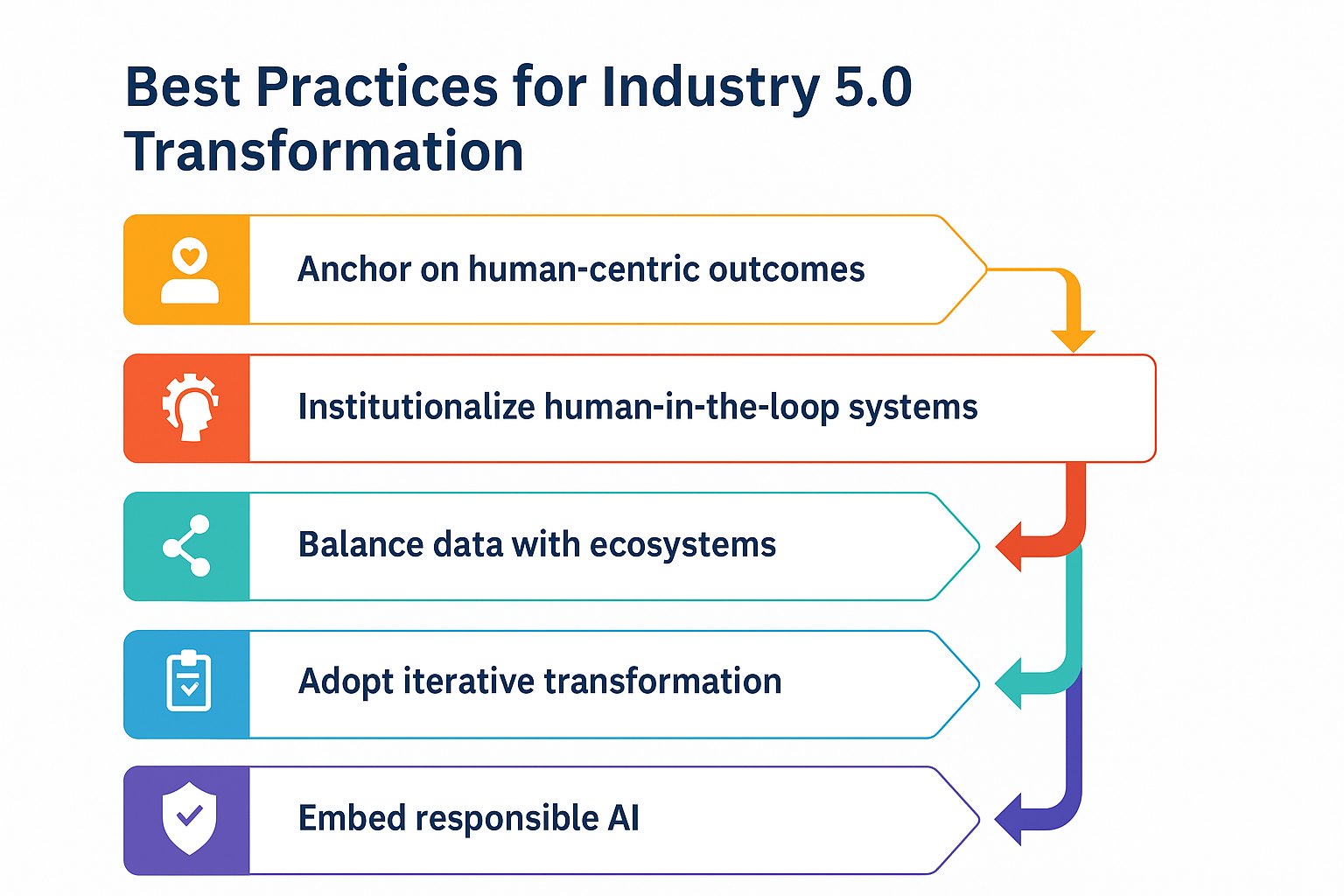

Best Practices for Industry 5.0 Transformation

Transitioning to Industry 5.0 is not about technology adoption alone. It requires deliberate choices in governance, culture, and execution. Organizations that succeed share a common playbook:

- Anchor on human-centric outcomes: Prioritize customer trust, employee safety, and sustainability alongside ROI.

- Institutionalize human-in-the-loop systems: Ensure humans review, refine, and govern AI-driven decisions.

- Balance data with ecosystems: High-quality pipelines matter, but so do partnerships with suppliers, advisors, and regulators.

- Adopt iterative transformation: Pilot, measure, and scale, avoiding big-bang implementations that overreach.

- Embed responsible AI: Transparency, explainability, and compliance drive trust and adoption.

These practices separate performers, who achieve measurable ROI, from experimenters who stall in pilots.

Should Every Function Go 5.0?

Industrial enterprises operate with highly complex, vertically integrated processes, where systems, people, and technology are deeply interdependent. In such environments, transformation cannot be approached as an all-or-nothing exercise. Change management is critical to ensure augmentation happens without jeopardizing business continuity.

This raises one of the most common executive questions: Should every function transition to Industry 5.0? The answer is no. Transformation must be selective, strategic, and ROI-driven, with investments prioritized where they deliver the greatest business impact.

- High-ROI functions: Manufacturing, supply chain, and R&D deliver the fastest returns. Predictive maintenance alone can reduce downtime by 30–50%.

- Customer-facing areas: Personalization and AI-driven service can double or triple customer lifetime value.

- Selective modernization: Low-value functions such as payroll or AP may remain at Industry 4.0 with minimal downside.

Not every process needs to be “smart.” What matters is aligning Industry 5.0 initiatives with enterprise strategy and measurable value creation.

How to Prioritize & Manage the Transition

Managing the shift to Industry 5.0 requires as much attention to governance and people as to technology. Leaders who navigate this well treat transformation as a disciplined, staged process:

- Assess maturity: Use frameworks like Gartner’s maturity model or the EU Industry 5.0 Index to benchmark readiness.

- Prioritize ROI & feasibility: Focus on projects with <24-month payback (e.g., energy optimization, predictive maintenance).

- Establish governance: Create transformation councils bridging IT, operations, and business.

- Invest in talent: Schneider Electric retrained 60,000 employees in digital skills to accelerate adoption.

- Scale through agile pilots: Start with one factory, line, or business unit to prove impact and then replicate.

- Manage culture: Success depends on employees seeing themselves as participants, not subjects. Transparent communication is essential.

Deliberate, staged execution builds enduring competitive moats and avoids transformation fatigue.

Industry 5.0 is not a buzzword - it is already here. The winners of the next decade will be those that act now, blending human creativity with AI precision to deliver sustainable, resilient, and personalized value at scale.

👉 At

DX Advisory Solutions, we help enterprises design and execute Industry 5.0 strategies - from AI platforms and smart manufacturing to ESG-aligned digital transformation roadmaps. Let’s connect and explore how your company can lead - not follow - into the age of

People + AI collaboration.

About Author:

Towhidul Hoque is an executive leader in AI, data platforms, and digital transformation with 20 years of experience helping organizations build scalable, production-grade intelligent systems.