From Assistance to Autonomy: How AI is Redefining Digital Manufacturing

In manufacturing, each era has been defined by a transformative leap: mechanization, electrification, and digitization. Today’s leap is just as profound, the shift from human-assisted processes to AI-powered decision autonomy. This is not a future scenario anymore. In fact, it is already reshaping operations, driving measurable financial and operational gains.

At DX Advisory Solutions, we frame this evolution through four lenses: modern AI architecture, the foundations laid by past industrial revolutions, the journey to decision autonomy, and the tangible value across the manufacturing value chain.

Modern AI: Architecture, Capabilities, and Differentiators

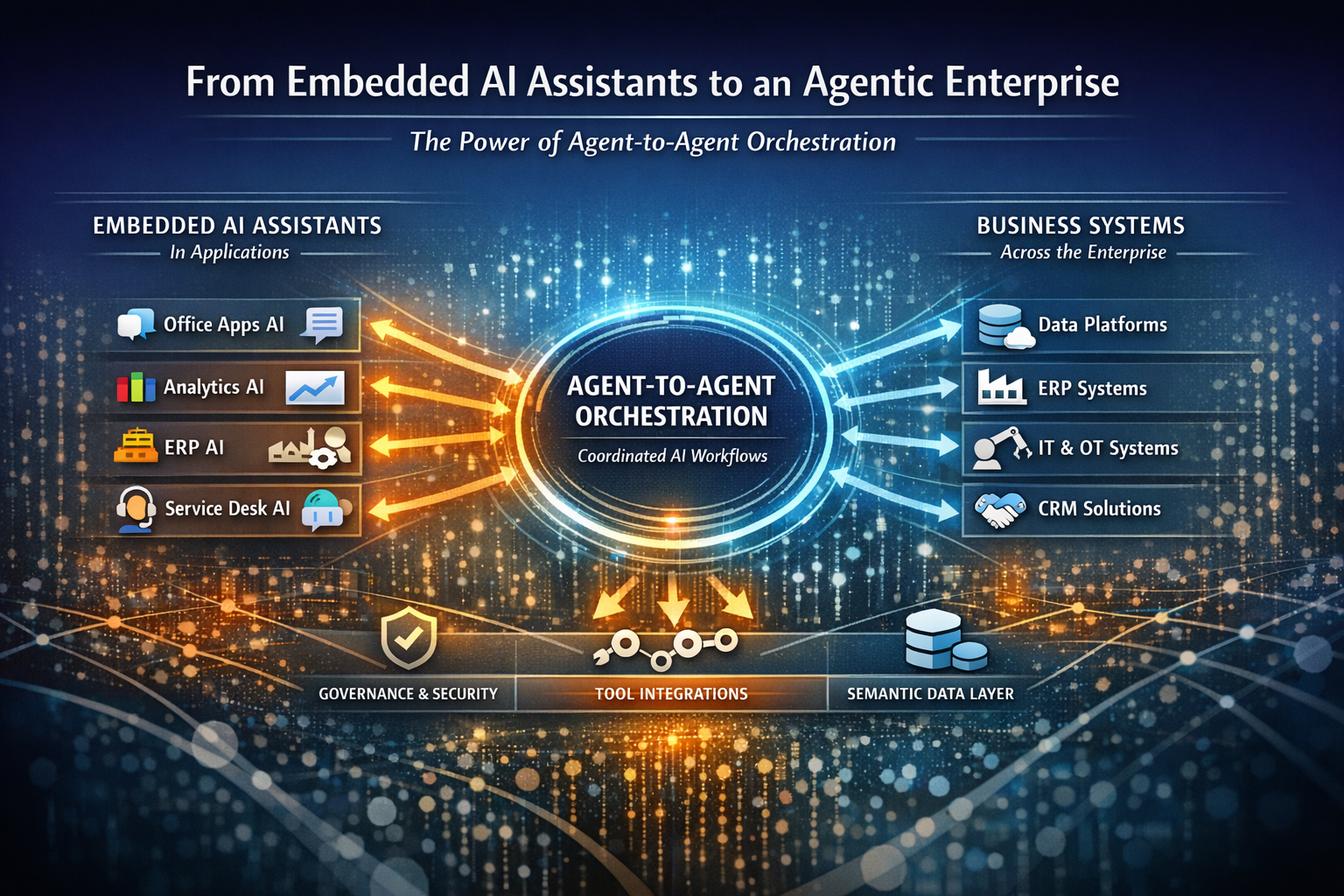

Modern AI is the convergence of decades of progress in algorithms, computing power, and enterprise system integration. What makes today’s AI transformative is how it blends multimodal generative and classical machine learning models with real-time data streams, orchestrating intelligence across the entire business technology stack.

In manufacturing and other complex industries, this means AI is no longer a “bolt-on” tool. It lives inside the workflows, connected to the systems that run operations, making decisions, coordinating actions, and learning from results. Its design reflects a multi-layered stack where foundational intelligence meets domain expertise, and where adaptability and autonomy are built in from the ground up.

- Architecture: The Multi-Layered Intelligence Stack

- Foundation Models: Large-scale language, vision, and multimodal models capable of understanding and generating across diverse data types.

- Classic ML & Statistical Models: Purpose-built algorithms for structured, domain-specific use cases such as forecasting, process control, and quality prediction.

- Real-Time Edge Sensing: Industrial IoT devices, PLCs, and vision inspection systems continuously streaming operational telemetry.

- Orchestration Layers:

Coordinating AI components with enterprise systems like CRM, ERP, MES, WMS, LIMS, CMMC, and SCADA via MCP to ensure AI is embedded where work happens.

- Capabilities: Generality, Adaptability, and Seamless Integration

- Generality: One model family can serve multiple use cases with minimal retraining, reducing deployment friction.

- Adaptability: Same AI backbone can be tuned to different operational contexts such as maintenance logs, product defect detection, or production schedule optimization.

- Interoperability:

Smoothly integrates with both operational (OT) and information (IT) systems, enabling end-to-end decision support and automation.

- Differentiators: Redefining Human-Machine Interaction

- Interface Shift: Move from static dashboards to conversational, natural language interaction where operators can instruct machines directly.

- Embedded AI Agents: Agents operate inside enterprise systems, interpret human intent, select actions, and execute them without manual intervention.

- Plan–Act–Verify Cycle:

- Plan: Break complex objectives into actionable steps.

- Act: Execute across multiple systems autonomously.

- Verify: Compare results to objectives, learn, and adjust actions in real time.

The Catalysts: Electrification and Digitization

Every leap forward in manufacturing has been powered by a foundational shift. The AI revolution we are witnessing today is no exception. It is built on the twin pillars of electrification and digitization. Without these earlier transformations, the conditions for AI’s rise simply would not exist. Let’s review these transformations briefly to find the continuity in transformations:

- Electrification: Powering the First Productivity Surge - The electrification wave replaced human muscle and steam-driven systems with automated, electrically powered machinery. This change enabled faster, safer, and more consistent operations. With electrical power, factories could adopt modular layouts, run machinery continuously, and integrate early forms of automated control. This shift unlocked unprecedented throughput, reduced production variability, and made high-volume manufacturing viable at scale.

- Digitization: Turning Process into Data - Decades later, the digitization era took manufacturing from clipboard checklists and paper-based records into interconnected digital systems. ERP platforms unified enterprise data, MES systems managed shop-floor execution, and SCADA systems provided supervisory control and monitoring. Together, they created the first truly data-rich manufacturing environments. Every machine reading, every production order, and every quality check could now be captured, stored, and analyzed.

- Laying the Groundwork for AI - Electrification gave manufacturing its body as mechanized, powered, and tireless. Digitization gave it a memory with precision, retrievability, and interconnectedness. These two revolutions also introduced the necessary infrastructure for today’s leap:

- IoT Connectivity: Machines and sensors that stream real-time telemetry.

- Asset Interoperability: Equipment and software that can communicate across OT and IT boundaries.

- Data Availability: Rich historical and live datasets for training and running AI models.

Now, AI is stepping in as the brain, enabling to process vast streams of structured and unstructured data, simulate outcomes, predict failures, and optimize processes at speeds and scales that human operators cannot match. The same electric motors and data streams that once powered and recorded manufacturing now feed intelligent systems capable of closed-loop control, scenario testing, and autonomous decision-making.

From Assistance to Autonomy: Tangible Impact Across the Manufacturing Value Chain

The move from AI as a passive assistant to AI as an active decision-maker is a structural shift in how manufacturing businesses operate. The technology is no longer simply surfacing insights for human review; it is increasingly orchestrating, executing, and verifying actions across the value chain. This evolution is reshaping both the front-end business processes that drive revenue and the shop-floor operations that define productivity, safety, and quality. Here is how that transformation looks in practice:

- Front-End Acceleration:

AI-driven CRM and ERP systems now act as proactive deal accelerators. By automating data ingestion, opportunity scoring, and bid preparation, they compress the Request for Proposal (RFP) cycle from weeks to days. Integration with supply chain data allows these systems to quote accurate delivery dates and pricing instantly, improving win rates in competitive B2B markets. Natural language interfaces and embedded agentic workflows mean that sales, operations, and logistics teams can collaborate in real time without the bottlenecks of manual data entry or interdepartmental delays.

- Self-Optimizing Plants:

Model Predictive Control (MPC) enhanced with AI continuously tunes production parameters, such as temperature, pressure, and flow rates, to optimize yield, product quality, and energy efficiency. The AI layer can process thousands of sensor readings per second, detect micro-shifts in process stability, and make minute-by-minute adjustments that human operators could not match in scale or speed. This results in reduced waste, more consistent output, and a lower carbon footprint.

- Predict-and-Prevent Maintenance: Traditional preventive maintenance relies on fixed schedules while predictive maintenance uses AI to detect anomalies in real time and forecast Remaining Useful Life (RUL) for critical assets. This shifts maintenance from reactive repairs to precision interventions. For example, vibration and thermal imaging data, fed into anomaly detection models, can predict bearing failures weeks in advance. In practice, this eliminates unnecessary shutdowns and has been shown, per recent field data, to cut unplanned downtime by over 30 percent.

- Industrial Digital Twins: Digital twins replicate plant operations in a virtual environment, enabling simulation of production changes, new product runs, or system upgrades before implementation. AI augments this capability by dynamically updating the twin with live plant data, allowing operators to run “what-if” scenarios that reflect real-time conditions. This shortens commissioning times, reduces the risk of costly trial-and-error, and makes process optimization a continuous activity.

- EHS & Compliance: In regulated industries, Environmental, Health, and Safety (EHS) compliance is non-negotiable. AI vision agents can automatically detect PPE compliance, identify hazards, and log inspection results with geotagged evidence. Automated documentation pipelines ensure that compliance reports are complete, accurate, and ready for audit at any time, reducing manual reporting burdens and minimizing the risk of non-compliance penalties.

A 3-Year Outlook for Agentic AI in Manufacturing

The manufacturing sector is standing at a tipping point where AI agents are evolving from experimental pilots to core operational infrastructure. Over the next three years, we expect a shift from selective deployments to full-scale integration, where AI no longer just supports decisions but actively drives them. This transition will be fueled by advances in industrial connectivity, more sophisticated AI orchestration, and a workforce ready to operate alongside intelligent systems.

Here is how we see this unfolding:

- Agentic AI Becomes Standard: Embedded in MES, CMMS, and DCS with improved root cause resolution and faster changeovers.

- Scale Across Value Chains: Full digital twin adoption enables end-to-end optimization.

- OT/IT Convergence: Unified, secure data across operations; AI inference at the edge for real-time responsiveness.

- Workforce Evolution: Engineers become AI operators with governance being embedded into workflows.

These outcomes depend on stable access to compute, a maturing vendor ecosystem, pragmatic AI risk frameworks such as the NIST AI RMF, and robust cybersecurity to protect OT networks from emerging threats.

Why It Matters Now

Agentic AI is not distant. Rather, it is delivering tangible value today. Industry trends and data prove that intelligent agents can save time, cut costs, and free humans for greater thinking. Combining that with AI’s evolution on the factory floor opens a new frontier in manufacturing - efficiency, autonomy, and adaptability - without sacrificing control or safety. This evolution is as significant as electrification or the digital pivot. The key to success lies in early adoption, holistic integration, and responsible governance.

Call to action

Ready to evaluate the readiness for AI-driven decision autonomy to identify high-impact opportunities and define a clear integration roadmap? Book a 30-minute advisory session with DXAS.

About Author:

Towhidul Hoque is an executive leader in AI, data platforms, and digital transformation with 20 years of experience helping organizations build scalable, production-grade intelligent systems.