Agentic AI in Industrial Manufacturing: Redefining Supply Chain Intelligence

In the era of smart manufacturing, the next frontier in AI evolution is Agentic AI—a paradigm shift from passive, task-specific models to autonomous, goal-oriented agents. For industrial manufacturers navigating increasingly complex supply chains, Agentic AI offers the promise of real-time adaptability, intelligent decision-making, and system-wide optimization. This blog explores what Agentic AI is, how it differs from traditional AI, its applications in industrial supply chains, implementation principles, and the challenges ahead.

What Is Agentic AI and How Is It Different from Traditional AI?

Agentic AI refers to systems that can perceive, plan, decide, and act autonomously to achieve high-level objectives with minimal human intervention. Unlike traditional AI, which typically responds to inputs with pre-trained predictions (e.g., identifying defects or forecasting demand), Agentic AI can:

- Formulate its own subgoals to complete complex tasks

- React to environmental changes in real-time

- Learn from feedback and adapt over time

- Collaborate with other agents and systems

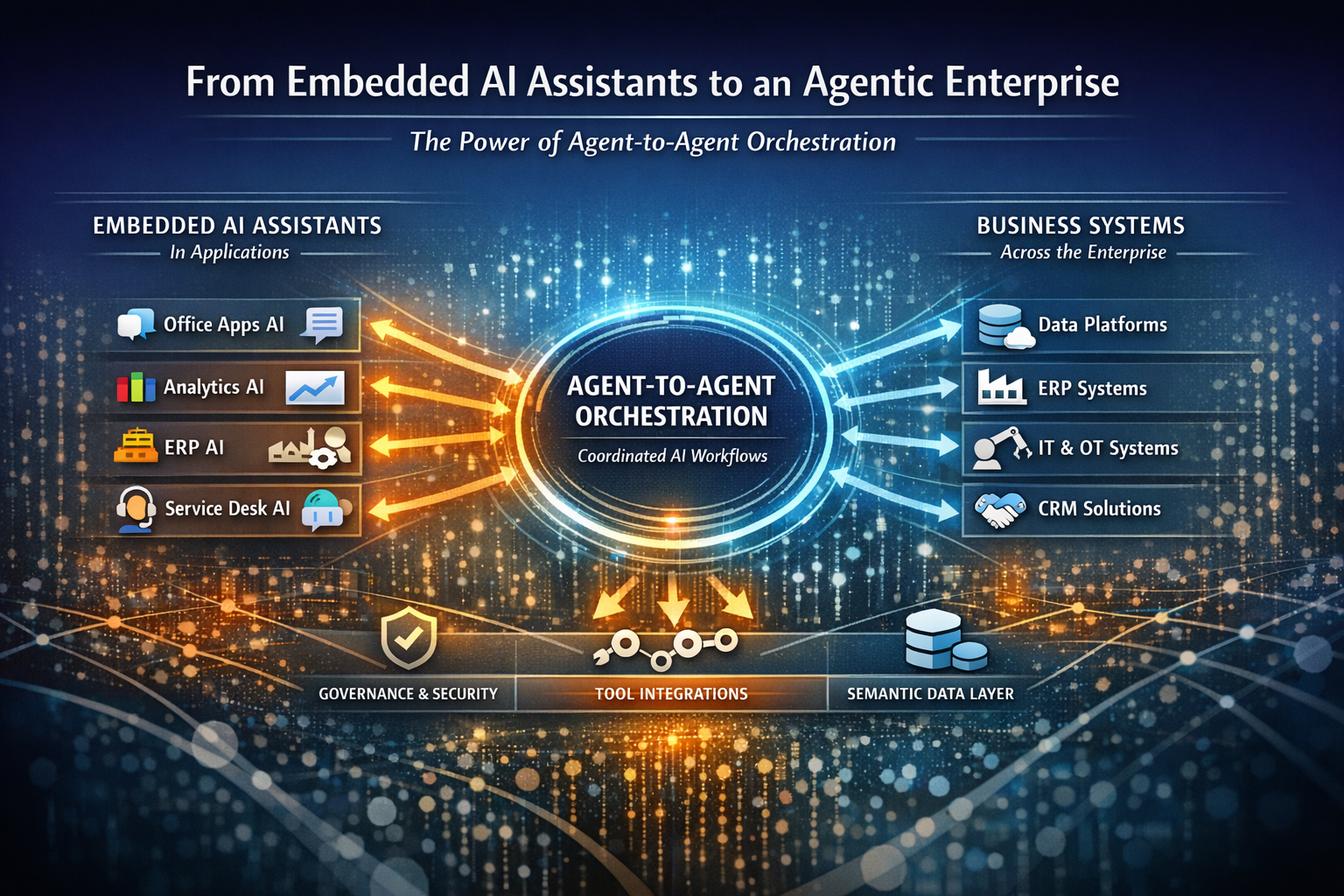

Whereas traditional AI is often embedded into narrowly scoped tools (e.g., predictive maintenance, quality inspection), Agentic AI acts as a "digital co-pilot" or autonomous worker that drives end-to-end workflows with strategic awareness.

McKinsey defines Agentic AI as "AI that can reason, act independently, and dynamically adapt to context" — a core enabler of autonomous operations.

Opportunities in Industrial Supply Chains

Modern supply chains are highly complex, spanning global networks, fluctuating demand signals, volatile raw material costs, and unpredictable disruptions. According to a recent Deloitte survey, 79% of manufacturing executives say supply chain visibility is their top challenge in digital transformation.

Agentic AI introduces several breakthrough opportunities:

- Autonomous Procurement Agents: Dynamically negotiate contracts, compare supplier risk, and optimize for cost, carbon footprint, and lead time.

- Smart Inventory Optimization: Automatically adjust inventory buffers and safety stock policies based on real-time demand, supplier behavior, and transportation conditions.

- Resilient Logistics Planning: Reroute shipments, reallocate resources, and simulate alternative fulfillment paths when disruptions occur.

- Predictive Maintenance Orchestration: Agents coordinate scheduling, parts ordering, and technician dispatch autonomously, reducing unplanned downtime.

Accenture reports that AI-driven supply chain optimization can reduce logistics costs by 15% and inventory levels by up to 35%.

How to Use Agentic AI: Implementation Principles

To successfully deploy Agentic AI in manufacturing supply chains, companies should follow these best practices:

- Define High-Impact Use Cases

Start with critical pain points like last-mile delivery, supplier reliability, or factory-floor rescheduling. Use scenario planning and business KPIs to guide agent objectives. - Establish Digital Twins and Real-Time Data Streams

Agentic AI thrives on real-time context. Invest in IoT-enabled assets, cloud data lakes, and digital twin architectures to provide situational awareness. - Integrate with Human-in-the-Loop Governance

While autonomous, agents should remain transparent and auditable. Enable supervisory control, decision overrides, and model explainability. - Leverage Multi-Agent Systems

Use fleets of agents that coordinate across functions—from procurement to logistics—to optimize the full value chain. - Ensure Interoperability and API-First Design

Agentic AI should plug into existing MES, ERP, and SCADA systems using standardized APIs and event-driven architectures.

Challenges and Risks

Despite its promise, Agentic AI poses real implementation and ethical challenges:

- Model Robustness: Agents must perform reliably in dynamic, high-stakes environments with sparse or noisy data.

- Security and Adversarial Threats: Autonomous systems are vulnerable to manipulation and cyberattacks.

- Change Management: Shifting from human-driven processes to agentic workflows can trigger resistance and skill gaps.

- Ethical and Regulatory Oversight: Autonomous decision-making must comply with safety, labor, and accountability standards.

According to PwC, only 16% of industrial firms report that their AI governance programs are "mature," exposing significant readiness gaps for advanced autonomy.

Final Thoughts

Agentic AI is not science fiction—it is the next evolution of industrial intelligence. By combining autonomy, context-awareness, and real-time responsiveness, Agentic AI can empower supply chains to become more resilient, efficient, and adaptive.

Manufacturers that invest early in this capability will gain not only operational advantages but also strategic differentiation in a competitive global landscape. The key is to approach Agentic AI with a balanced focus on technical innovation, organizational readiness, and ethical design.

About Author:

Towhidul Hoque is an executive leader in AI, data platforms, and digital transformation with 20 years of experience helping organizations build scalable, production-grade intelligent systems.